Machines for printing and labeling

With a PPS solution you will achieve increased flexibility and faster time to market. Whether you want to print directly on the product or on a label you can achieve a number of benefits in your production, including:

• Reduced waste and storage space

• Print on demand

• Lower unit costs

• No change-over time

• Agile marketing campaigns and individualized information

Choose the best solution

Which solution you choose for printing variable data and branding messages on your products, is highly dependent on batch sizes.

In most cases, digital inline printing is the optimal solution, especially if there are many product variants or the products are sold in many different countries.

If it is a large volume production with few variants for a limited number of markets, a pre-printed label may be the most effective choice, in combination with a labeling solution from PPS.

For small batches, with many different product variants, late-stage customization is ideal. With late-stage customization the country- or customer-specific data is printed only after the product has been ordered. Moreover, the final adjustment can be done on site, resulting in a very agile supply chain and significant reductions in inventory binding.

PPS is happy to assist in calculating a non-committal business case on which setup gives you the lowest unit cost and the most flexible production.

Contact us for a discussion about the possibilities in digital printing and labeling.

Print directly on the product

Market trends point to increased flexibility, for example through streamlining processes, agile marketing campaigns, and shorter time to market.

The caps in the image on the left illustrate just one of the countless possibilities of printing directly on the product.

At the same time, it provides a fine example of how the use of digital printing can provide increased differentiation, which can ultimately lead to greater brand value and significant increases in sales.

In addition to branding and marketing messages, digital printing directly on the product is ideal if you need to print variable data. Variable data is, for example, serialization codes, individualized competition data or 2D codes that can be scanned with the customer’s mobile phone and link to a website with product information.

With digital printing, you can go from pdf to a printed product in just a few hours, and the time to market is greatly reduced compared to traditional analogue printing. The design can be corrected and tested on site, and as soon as the approval is available, you are ready to print.

Some of the many benefits are:

• Countless options for individual customization

• Greater flexibility in format and design

• Reduced waste

• Less stock binding

• From pdf to printed product in a few hours

Labeling for everyone

PPS provides all types of labeling solutions, ranging from simple manual label dispensers to high-tech bespoke inline printing and labeling systems.

The heart of our labeling solutions is a Herma 500 dispenser, which is presented in the video to the right. Herma 500 is of the highest quality and delivers labeling at high speed and high precision. Furthermore, it is compatible with Industry 4.0 and can be combined with various printers, as well as vision and control systems.

If the right labeling solution is not available as a standard model, we design and deliver solutions that are adapted to your needs and requirements. Such a solution can be anything from placing a label on an item on an existing conveyor belt, to a fully automated assembly, labeling, and packaging line.

Common to all solutions is that we supply labeling machines with powerful functions, high labeling accuracy and significant production savings.

Market leading solutions

PPS provides solutions for printing data and graphics on all types of surfaces and all types of labeling material. All solutions can increase the flexibility of your production. Read more about the different options by clicking on the bars below to unfold the text.

INLINE PRINTING AND LABELING ⇒ click to unfold

Inline printing and labeling are designed to be an agile process without having to compromise on speed, quality, or reliability of the production. It is an efficient and time-optimizing solution, as there are fewer steps in the process since packaging, printing, and labeling take place on the same line.

Inline printing can be realized with both digital printing and traditional flexo printing. However, the benefits of digital printing also apply here.

With inline digital printing and labeling, there is also ample opportunity to make use of late-stage customization. With late-stage customization you have the opportunity to produce the product and wait to print the variable information for when you need it.

For example, if you make blister cards, the blister cards can be produced and stored. Only when you receive an order do you print the country- and product-specific information. Thus, you only need to have neutral blister cards in stock and not in all variants.

PRINT ON PLASTIC ITEMS AND MEDICAL EQUIPMENT ⇒ click to unfold

Thanks to digital printing technology, you can advantageously choose to print directly on plastic items, such as caps or toothbrushes; or on medical devices, such as syringes or ostomy bags. This presents several advantages over printing the information on labels.

Without the use of labels, less material is used and consequently you will get less waste. In addition, there is no need for pressure plates, as with flexo printing. This results in lower costs, both associated with the production of the printing plates and with less material consumption.

With digital printing there are fewer preparations before production and between product changes, as there is no need to change printing plates, mix ink, or run test prints. Moreover, digital printing is better for the environment for several reasons. Besides less waste, as mentioned above, there is a lower ink consumption, as ink is only used on the print itself. There are no start-up sprints and there are no printing plates filled with ink to be cleaned after each run.

Digital printing can also be combined with Blow-Fill-Seal (BFS) technology. By implementing a print unit in the BFS process, one can print directly on the products in the same process. This provides both an efficient and economical solution, as costs and the extra time associated with either embossing or labeling are removed. For an example of the process watch the video below.

PRINT ON PACKAGING ⇒ click to unfold

Packaging has become an important sales parameter and digital printing offers new opportunities in the battle for customers.

With digital printing technology you can also make use of late-stage customization, where you can individualize the packaging at the last minute, by simply having neutral packaging in stock.

One of the many advantages of printing directly on the packaging is that you achieve a more flexible production process, less waste, and reduced time to market.

With the high degree of individualization that digital printing technology offers, brand owners get countless opportunities to customize their packaging and through late-stage customization each package can be made unique.

In addition, serialization codes and other variable data can be printed directly on the packaging, making it even more difficult to counterfeit the product. Digital printing directly on the packaging thus provides increased security for the product’s originality to both brand owners and consumers.

LABELING ⇒ click to unfold

Labels comes on numerous products and in a myriad of varieties. They may be wrapped around a cylinder, such as cans or vials; or they may be on the side, top, or bottom of a product. They can be shaped like an L or C and placed so that they cover the opening. Thereby, they also serve the purpose of showing whether the product has been opened before, by the label being broken – so-called tamper-evident labeling.

Environmentally friendly labels for packages

Latest technology provides highly environmentally friendly labels. With the Herma InNo-Liner system, you get labels that only stick when they come in contact with water. This leads to a substantial decline in waste, as the labels are linerless, meaning there is no liner material to simply discard once the labels have been removed.

Like traditional labels, the InNo-Liner label material also comes on a roll. The reason is that the back of the labels only sticks when it is added the right amount of water. Since there is no liner material on the labels, each roll can have more labels, thereby reducing both shipping weight and required storage space. In addition, the cost of discarding the liner material from the labels is eliminated.

PPS sells labeling machines for all these types of labels. Solutions range from simple manual dispensers placed on a table to custom PPS-designed labeling machines that can be implemented in larger lines.

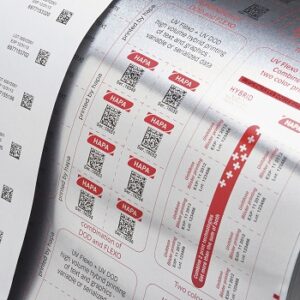

PRINT ON BLISTER FOIL ⇒ click to unfold

Traditionally, one would use a flexo printer to print information on blister foil, run large batches, and then store the various variants. As the need increases for smaller batches and more frequent product changes, along with continuing price pressure, the traditional flexo printer is in many cases no longer the optimal solution. For small and medium batches, digital printing is often a more economically advantageous solution.

With a digital printer the time you need to switch between print jobs is largely eliminated. Printing plates are not needed, as is the case with flexo-print; instead, you simply upload a pdf file with the design to the machine. Thus, you no longer need to have all variants of blister cards in stock, as you can print in line with demand.

If, on the other hand, your need remains large batches with few product changes, flexo-print will most often still be the right solution. The size of your batches is therefore very much decisive for which type of printer is the best and most economical solution.

Opportunities with digitally printed codes

It can be difficult to imagine how digital printing can benefit exactly your business. Many focuses on the information traditionally added, such as product info, brand, and serial number. But if you think about the possibilities in a larger context and see it in the light of the constantly growing digitalization, it may bring new opportunities.

An example of this comes from a retailer of office and stock items. We all know about the problem with a seemingly endless catalog and 17 different variants within the same product category.

Using digital printing, the manufacturer can print, for example, a QR code on each product. When the customer once a year needs to change the stock broom, he can scan the code using his smartphone. He will then be sent directly to the webshop under the correct product.

The user experience for the customer is thus completely different than if he had to search the entire webshop for the same broom; or worse, get tired of searching and buying a broom from the competitor instead.

Do you want us to call you?

Fill out the form below with your contact information and we will contact you as soon as possible.

You are welcome to make a note if there is something specific you want to discuss.

Shorten time to market

with print on demand

Benefit the environment

by reducing waste

Automate processes

through collaborative robotic arms or other types of automation

Offer unique knowledge

when we collaborate in finding the optimal solution for your production

Increase flexibility

with printing and labeling

Reduce storage space

by shifting from pre-printed labels

Eliminate change-over time

by printing all labels on the same roll

More branding options

with an increased degree of individualization and printing directly on the product

RE

PPS partner Hapa, together with two partners, delivered a digital printing solution for the Italian beverage manufacturer Lete S.p.A.

With the print solution from Hapa, 20 different emoji motifs were printed directly on the caps for Lete’s mineral water Acqua Lete.

Lete ran a large brand campaign, called “letemoji”, for their mineral water, with the objective of inspiring consumers to collect all 20 different emojis and thus extend the awareness of the Acqua Lete mineral water.

The technology that allows you to make four-color printing directly on the caps – or another surface – provides countless possibilities for branding, but also for printing codes and other variable data.

Contact us for a discussion about the possibilities of digital printing on your product and let us find the best solution together.